The European Shipper's TMS Automation ROI Framework: How to Build Bulletproof Business Cases That Survive CFO Scrutiny While 76% of Digital Transformation Projects Fail to Meet Targets

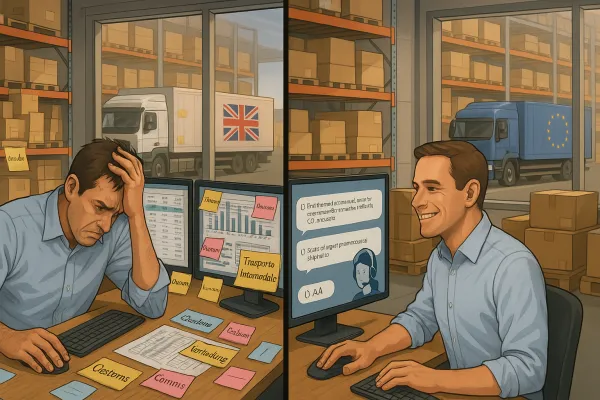

The CFO summons you to discuss your TMS automation ROI proposal again. Third time this quarter. You've watched colleagues across the hall get approval for fleet management software while your transport management system request sits in bureaucratic limbo. The numbers look good on paper, but something feels missing.

Here's the uncomfortable truth: 70% of digital transformation initiatives still fail to meet their objectives in 2025, despite years of effort and trillions spent, and TMS implementations face similar odds. With the global spend on digital transformations set to reach $3.4 trillion by 2026 according to IDC, and research by McKinsey (amongst others) stating that roughly 70% of these fail to deliver successful outcomes, European transport managers need a fundamentally different approach to building transport management system business cases that survive the scrutiny.

The €2.5 Million Automation Gap: Why Most European TMS Business Cases Fail

Your current business case probably looks like everyone else's. It promises operational efficiency, cost savings, and "digital transformation benefits" without concrete metrics. Sound familiar?

A German automotive parts manufacturer invested €800,000 in SAP TM implementation, only to discover six months later their new system couldn't handle their complex carrier network spanning 12 countries. The problem wasn't the technology. It was the business case that focused on theoretical benefits instead of measurable, European-specific requirements like eFTI compliance and cross-border documentation.

According to Gartner®, "Failure to understand your organization's level of transportation complexity and lack of a clearly defined scope of the proposed transportation management system (TMS) solution can significantly impact its projected ROI." This hits differently when you're managing multi-modal shipments across Rotterdam, Hamburg, and Antwerp with varying customs requirements.

Traditional TMS business cases fail because they treat all transportation operations as equivalent. But European shippers face unique complexities: GDPR compliance for shipment data, varying VAT structures across member states, and carrier integration challenges that American-focused vendors often underestimate.

The Hidden Cost of Manual Processes That CFOs Miss

Finance teams see the €150,000 annual software license. They miss the €78,000 opportunity cost of manual processes that automation eliminates.

If your transport coordinators spend 15 hours weekly on manual carrier selection, rate comparisons, and documentation at a €60,000 annual salary, that's €22,000 in opportunity cost annually. Automated systems optimize routing, consolidate shipments, track accessorial trends and identify recurring cost leaks that human teams often overlook.

The math gets compelling when you scale across European operations. Modern Transportation implemented BeyondTrucks TMS across 20 terminals, leading to approximately $5 million in annual savings by minimizing invoice errors and optimizing asset utilization. That's €200,000 per terminal in verifiable cost avoidance.

The 2026 Automation Business Case Framework: Beyond Theoretical Benefits

Forget the traditional ROI calculations that promise everything and measure nothing. The 2026 framework builds business cases around measurable cost avoidance and productivity gains, structured around five quantifiable categories that CFOs can verify independently.

Start with baseline measurement. Even a 2–3% drop in freight cost during week two sends a strong message—especially on a $500K monthly freight budget, that's $10–15K saved in just days. Your business case needs this level of granularity.

When evaluating vendors, compare how Cargoson's cloud-native approach stacks against established players like Manhattan Active or MercuryGate. Each offers different ROI profiles based on implementation complexity and European market focus. Cloud solutions typically show faster time-to-value, which matters when your payback period determines approval.

The Five-Category ROI Calculation Method

Administrative Efficiency Gains: Calculate exact hours saved through automated planning. According to Gartner®, "automation capabilities could generate an ROI of between 1% and 3% on freight cost savings alone for your organization." For a company with €10 million annual transport spend, that's €100,000-€300,000 in verified savings.

Route Optimization Savings: Document current routing inefficiencies versus optimized alternatives. A well-optimized TMS typically generates 15 to 25% kilometer savings, with the average cost of €0.45 per kilometer for utility vehicles across Europe. On 2 million kilometers annually, that's €135,000-€225,000 in fuel cost avoidance.

Error Reduction Benefits: Quantify current dispute resolution costs and billing discrepancies. Gartner® finds optimization features can contribute up to 15% ROI. Organizations typically see 5–10% savings on freight budgets by automating rate comparisons, according to Descartes. Manual processes generate billing errors that automated systems eliminate through real-time validation.

Carrier Performance Management: Measure the cost of using suboptimal carriers due to manual selection processes. Gartner rates the ROI of procurement capabilities at "between 2% and 10%." Gartner® calculates the ROI of analytics capabilities at "between 1% to 3%." Better carrier selection reduces transit times and improves service reliability.

Compliance and Documentation: Factor in the cost of GDPR violations, customs delays, and audit preparation. With eFTI compliance requirements starting January 2026, manual documentation processes become liability risks that automation mitigates.

Real-World European Success Stories: What Actually Works

A U.S.-based shipper using Kuebix achieved $2.2 million in logistics cost avoidance in one year—thanks to automated rate comparisons and real-time shipment tracking. The European equivalent would need to account for VAT implications and multi-currency operations, but the fundamental ROI drivers remain consistent.

Princeton TMX client Custom Glass Solutions achieved 20× ROI on their TMS investment within six months by automating previously manual LTL processes. This success came from focusing on specific, measurable workflows rather than broad "digital transformation" goals.

Gartner® estimates automation can yield 1–3% freight cost savings—and free countless hours of admin work. End-to-end digitization—from order creation to EDI invoicing—eliminates emails, spreadsheets, and redundant data entry. These aren't theoretical benefits. They're measurable outcomes that translate directly to profit impact.

Industry Benchmark Data for European Markets

A well-implemented TMS can deliver measured ROI in the range of 2% to 15% from optimization capabilities alone, depending on how much workflow standardization and automation you actually adopt. The variance depends on implementation quality and user adoption rates, not just the software selection.

Freight audit and payment functionalities help identify billing discrepancies that manual processes miss. Companies using TMS solutions report average 8% reduction in transportation costs and 10% improvement in delivery times, with Coca-Cola recovering over $2 million in billing discrepancies during their first year of automated freight audit.

These numbers matter because they're verifiable. Finance teams can audit the calculations and confirm the results independently, which builds confidence in the business case methodology.

The 2026 Implementation Timeline: Avoiding the 40% Failure Rate

While a majority (56%) of respondents said their organizations have achieved most or all of their transformation goals, only 12% report they have sustained these goals for more than three years. Additionally, an average 42% of financial benefits are lost during the latter stages of a large-scale change effort. This data shapes implementation strategy.

Q2-Q3 2025: Core system implementation and testing with limited AI features activated. These barriers explain why many organizations are adopting hybrid approaches for now: partial automation with human oversight in critical areas. Start conservative and build confidence.

Q4 2025: AI feature activation after proving core system stability. Most companies realize a full return on their TMS investment within 6 to 18 months when adoption is real and processes are standardized. Rushing AI deployment before establishing baseline processes increases failure risk.

Q1 2026: eFTI compliance preparation becomes mandatory as platforms can start preparing for operations beginning January 2026. European shippers need this timeline built into their implementation schedule.

CFO-Ready Business Case Template and Common Objections

When finance teams say "We can manage with Excel and email," counter with the quantified cost of manual processes. If coordinators spend 60 hours monthly on tasks that TMS automates in 15 hours, that's 45 hours of freed capacity monthly. Most teams underestimate the real cost of manual logistics tasks. Suppose your operations staff costs $40/hour. If GoComet eliminates 60 hours of manual work in the first month, that's $2,400 in immediate productivity gains.

Address "implementation risk is too high" concerns with phased rollout plans and vendor references. While long-term ROI is promising, initial investments, in technology, training, and data infrastructure, may still be significant. Cost of Transition becomes manageable when spread across implementation phases with measured ROI at each stage.

Your financial analysis should include total cost of ownership over three years, annual benefits by category with supporting benchmarks, ROI calculation with payback period, and sensitivity analysis showing impact of adoption rates. When you present automation as a cost reducer and a revenue generator and have the formulas to back it up, you build a business case that is nearly impossible to ignore.

The Vendor Selection Impact on ROI

Traditional on-premise solutions like SAP TM offer deep functionality but longer implementation cycles. Cloud-native alternatives like Descartes, Cargoson, or FreightPOP reduce setup complexity and accelerate time-to-value. Enterprise-level platforms (e.g. MercuryGate, Descartes) may require six-figure setups—factor in long-term ROI.

European considerations add complexity that American vendors often underestimate. Multi-country operations require VAT handling across different jurisdictions, eFTI compliance capabilities, and carrier integration for European networks. APIs enable tighter integration between TMS, warehouse systems, fleet telematics, and customers. Bridging data silos and delivering a unified view of operations, critical for scalable transportation management technology.

Compare vendor approaches to these requirements during evaluation. Solutions that handle European complexity natively will show faster ROI than platforms requiring extensive customization for European operations.

The CFO meeting approaches again. This time, your business case contains verifiable metrics, phased implementation timelines, and specific European compliance requirements. Instead of promising theoretical benefits, you're presenting measurable cost avoidance that finance teams can audit independently. That changes everything.